Facade Logistics

Years of transporting curtain wall panels of all different sizes from overseas and nationally has given Kingswood Aluminium the opportunity to refine a logistics method suited to every project.

Kingswood Aluminium starts planning the transportation of a curtain wall panel at the initial design stage. Identifying site installation challenges early on and developing installation sequences based on the builders construction stages.

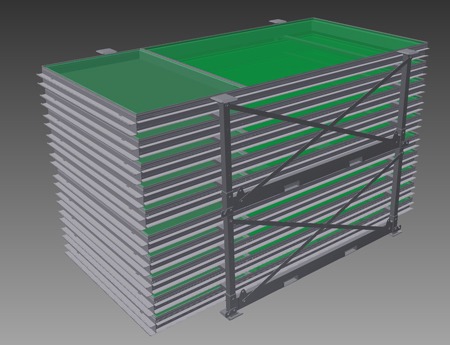

Transporting Curtain Wall

Transporting curtain wall panels from factory to site without damage can be challenging. As well as moving and maneuvering them onsite. To overcome these challenges, Kingswood Aluminium has developed a unique stillage called the K-Stillage. The K-Stillage can be adapted to carry varying depth curtain wall panels, varied sizes and lengths. The stillages allow for easy and stable stacking and are optimised to fit shipping containers.

The K-Stillage is easily maneuvered onsite. Each stallage is tested to Australian Standards to be crane lifted, carried on fork or rolled on removable trolley wheels.

After the panels are unpacked, the K-Stillage collapses down to a crate style assembly for easy removal from site and shipping back to our warehouse.

Kingswood Aluminium are certified to AS/NZS ISO9001 Quality Management Systems for the Supply of Architectural and Specialised Aluminium, Glass, Cladding and Facade Systems The ISO9001 standard contains requirements for a Quality Management System, which are used by Kingswood Aluminium to demonstrate its capability to meet client satisfaction and for assessment of the system by our own internal auditors and external parties. The Management System requirements provided in our Quality Manual are complimentary to specified technical requirements for Kingswood Aluminium’s product, services and procedures. This Quality Manual forms part of the quality system operating within Kingswood Aluminium Pty Ltd, in accordance with the AS/NZS ISO9001: 2008

Contact Us

140 Daws Road | Melrose Park | SA | 5039

+61 8 8277 1199

admin@kingswoodalum.com.au